Features

Lightweight and cost-effective

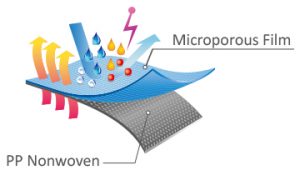

The light microporous fabric offers comfort and protection against hazardous liquid splash and particulates.

Exceeds EN 368 & EN 14126

Provides protection against biological hazards, the performance levels exceed the WHO protective clothing specification option 1 for Ebola infection control. [Note *]

Good breathability

High water-vapour transmission & soft texture ensures wearer comfort.

Low linting

Reduces the risk of fiber contamination to the work environment.

Note*: The WHO recommended specification for coveralls against filovirus disease issued in Oct, 2014 stated that healthcare workers should choose appropriate protective apparel, which meets the following two requirements:

option 1, tested for resistance to blood and body fluid penetration: meets or exceeds ISO 16603 class 3 exposure pressure.

option 2, tested for resistance to blood-borne pathogen penetration; meets or exceeds ISO 16604 class 2 exposure pressure.

![]()

![]()

![]()

![]()

![]()

- TYPE 5 EN ISO 13982-1 Dry Particle Suits-Suits for protection against hazardous dusts and any dry particles.

- TYPE 6 EN 13034 reduced spray -suits which offer limited protection against a light spray of liquid chemicals.

- EN 14126 Protective clothing can resist against biological hazards and infective agents.

- EN 1073-2 Protective clothing against particulate radioactive contamination.

- EN 1149-5 Electrostatic dissipative protective clothing with a surface resistance of maximum 2.5×10 exp 9 ohm.