Welding exposes workers to intense heat, sparks, UV radiation, toxic fumes, and flying debris. Proper PPE is critical to prevent burns, eye damage, respiratory issues, and long-term health risks. Here’s a breakdown of essential welding PPE:

1. Head & Face Protection

Welding Helmet with Auto-Darkening Lens

- Purpose: Shields eyes/face from UV/IR radiation, sparks, and spatter.

- Key Features:

- Auto-darkening lens (shade #8–13) instantly adjusts to welding arc brightness.

- Replaceable filters for grinding/torch modes.

- SafetyWare Example: Speedglas™ Auto-Darkening Helmets with respiratory compatibility.

2. Eye Protection

Safety Glasses/Goggles Under Helmet

- Purpose: Secondary protection against debris and slag.

- Requirement: ANSI Z87.1-rated impact-resistant lenses (clear or tinted).

3. Respiratory Protection

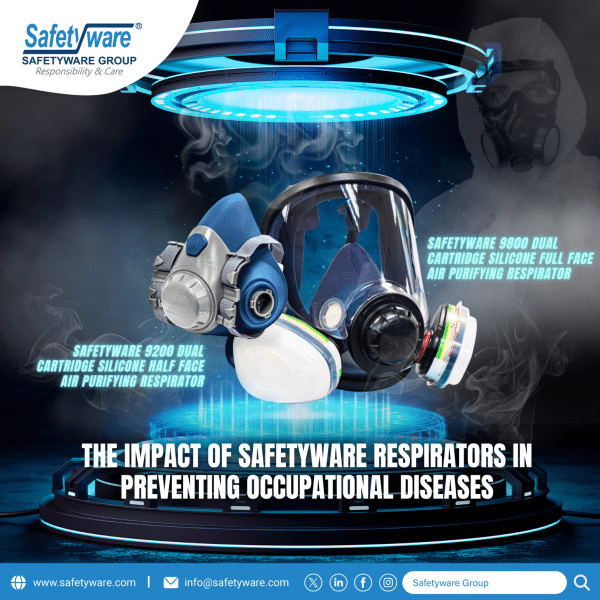

PAPR/Respirators

- Purpose: Filters toxic fumes (hexavalent chromium, ozone, metal oxides).

- Options:

- Disposable Masks: N95/P100 for light welding.

- PAPR (Powered Air-Purifying Respirator): For heavy welding; integrates with helmets.

- Elastomeric Half/Full-Face Respirators: With OV/P100 cartridges.

4. Hand & Arm Protection

Welding Gloves

- Purpose: Heat/spark resistance and dexterity.

- Types:

- Leather Gauntlets: For stick/MIG welding (heat resistance >932°F/500°C).

- TIG Gloves: Thin leather for precision work.

- Kevlar® Liners: Cut protection under gloves.

- SafetyWare Example: *Tillman® 50-Caliber Welding Gloves*.

5. Body Protection

Fire-Resistant (FR) Clothing

- Purpose: Prevents burns from sparks and molten metal.

- Essential Gear:

- Leather/FR Cotton Jacket & Apron: Covers torso and legs.

- FR Coveralls: For full-body protection.

- Avoid Synthetics: Materials like polyester melt onto skin.

6. Foot & Leg Protection

Steel-Toe Leather Boots + Metatarsal Guards

- Purpose: Protects feet from falling objects and sparks.

- Features:

- High-Top Design: Prevents slag entry.

- Heat-Resistant Soles: Resist melting (e.g., rubber or Vibram®).

- Spats/Leg Guards: Shield ankles.

7. Hearing Protection

Earplugs or Earmuffs

- Purpose: Reduces noise from grinding (100+ dB) and arc strikes.

- Options:

- Disposable Foam Earplugs (NRR 28–33 dB).

- Electronic Earmuffs: Allow speech communication.

8. Additional Safety Gear

- Welding Curtains/Screens: Protects bystanders from UV radiation.

- Fire Extinguisher: Class C (electrical) or Class K (chemical) for emergencies.

- Ventilation Systems: Fume extractors for confined spaces.

Safety Tips for Welders

- Layer Up: Wear cotton/wool under FR gear—never synthetic fabrics.

- Cover All Skin: Use balaclavas under helmets and button collars.

- Inspect Gear Daily: Replace cracked lenses, charred gloves, or damaged respirators.

- Stay Dry: Wet clothing increases electrical shock risk.

- Training First: Only certified welders should operate equipment.

Conclusion

Welding demands rigorous PPE to combat multiple hazards. From auto-darkening helmets to FR clothing and respirators, every layer is a life-saving barrier. Prioritize certified gear, regular maintenance, and ongoing training to ensure a safe worksite.

Explore SafetyWare’s Welding PPE today:

📞 Contact: [email protected]

🌐 Website: www.safetyware.com