LOTO (Lockout/Tagout) is a critical safety procedure designed to protect workers from dangerous energy releases during equipment maintenance or service. It involves separating energy sources and applying physical locks and tags to prevent accidental startup or energization.

Why Lockout/Tagout Matters

- Prevents Deadly Accidents:

Stops unexpected starting of machine that could cause crush injuries, amputations, or fatalities. - OSHA Compliance:

Mandated under 29 CFR 1910.147 – failure to comply risks heavy fines. - Safeguards Maintenance Teams:

Protects electricians, technicians, and cleaners servicing equipment.

Core Components of Lockout/Tagout

| Element | Purpose |

|---|---|

| Lockout Devices | Physical locks securing energy-isolating devices (e.g., circuit breakers, valves). |

| Tagout Devices | Warning tags (e.g., “Do Not Operate”) attached with locks to communicate hazards. |

| Energy Isolation | Complete disconnection from power sources (electrical, steam, gravity, etc.). |

When Is Lockout/Tagout Required?

Lockout/Tagout applies during:

- Equipment repair or maintenance

- Clearing jams

- Installing new Machine

- Any task needing workers to place body parts near dangerous moving parts.

Example: Locking transport belt before removing a jammed object.

6-Step Lockout/Tagout Procedure

- Prepare: Identify energy sources (electrical, hydraulic, thermal).

- Shut Down: Turn off equipment using normal controls.

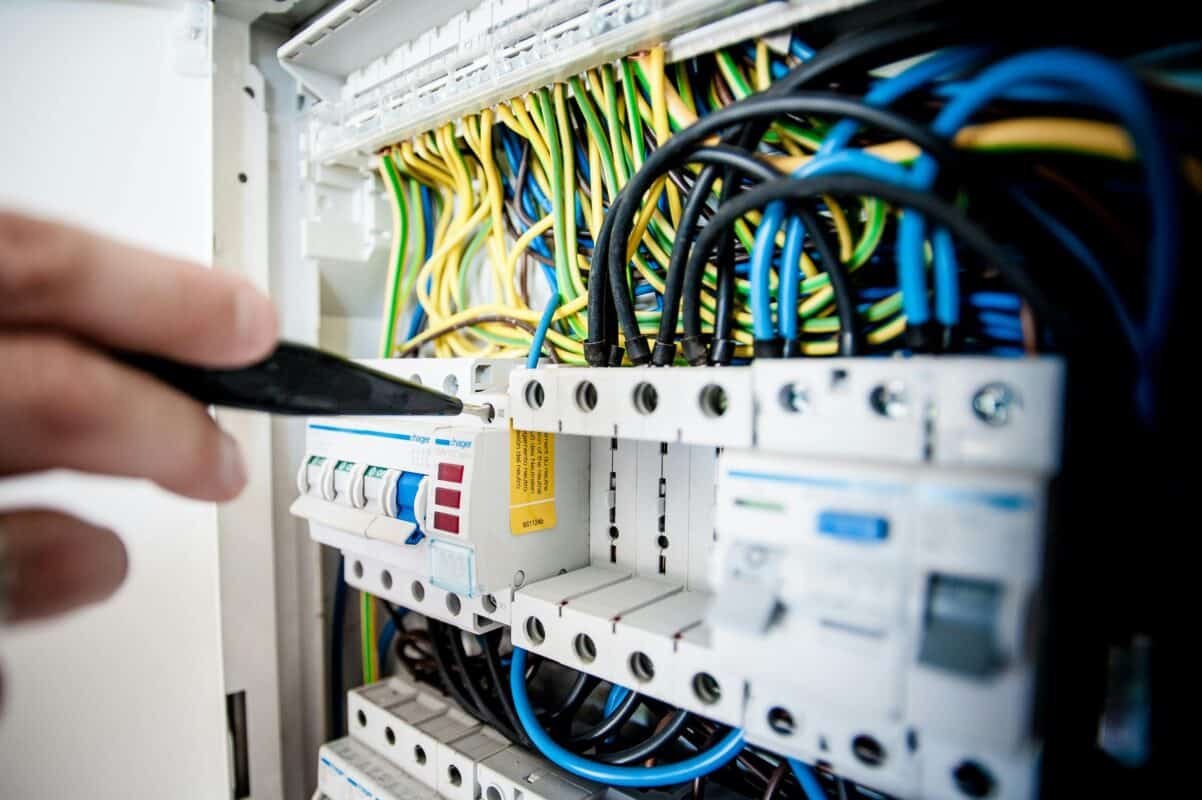

- Isolate: Disconnect all energy sources (e.g., flip breakers, close valves).

- Apply Locks/Tags: Each worker uses their own lock. Supervisors add tags.

- Release Stored Energy: Bleed residual pressure, release springs, block gravity driven parts.

- Verify: Test controls to ensure zero energy remains before starting work.

SafetyWare Lockout/TagoutSolutions

Ensure compliance with:

- Lockout Kits: Multi-lock systems for complex machinery.

- Circuit Breaker Locks: Securely isolate electrical panels.

- Valve Lockouts: For pneumatic/hydraulic systems.

- Training Kits: Employee certification materials.

“LOTO isn’t just procedure—it’s the barrier between maintenance crews and catastrophe.”

Prioritize safety. Implement Lockout/Tagout.

Explore SafetyWare’s LOTO products for OSHA-compliant energy control.

Explore SafetyWare’s LOTO solutions today:

📞 Contact: [email protected]

🌐 Website: www.safetyware.com