Why PPE is Important for the Pharmaceutical Industry

PPE plays a crucial role in maintaining the safety and integrity of pharmaceutical production. Workers in pharmaceutical environments are exposed to hazardous substances, including active pharmaceutical ingredients (APIs), chemicals, and potential biological contaminants. Without proper PPE, these risks can lead to contamination of drug products, affecting both their efficacy and safety. Additionally, PPE safeguards workers from occupational health hazards, ensuring compliance with regulatory standards such as Good Manufacturing Practices (GMP). The correct use of PPE minimizes the risk of cross-contamination, ensuring that pharmaceutical products meet strict quality and safety guidelines.

Types of Contaminants in Pharmaceutical Production

1. Microbial Contamination

Bacteria, fungi, and viruses pose significant risks in pharmaceutical environments. Even a single microbial presence can render an entire batch of medicine unsafe for use.

2. Particulate Contamination

Dust, human skin flakes, fibers, and other microscopic particles can alter drug formulations and impact their effectiveness.

3. Chemical Contamination

Unintended chemical residues from cleaning agents, raw materials, or cross-contamination from other drugs can lead to hazardous consequences.

Essential PPE for Pharmaceutical Workers

1. Gloves

Gloves act as a barrier between the worker’s hands and pharmaceutical products, preventing the transfer of microbes and particles. Nitrile, latex, and neoprene gloves are commonly used due to their durability and resistance to chemicals.

2. Face Masks & Respirators

Masks and respirators prevent airborne contamination by blocking the release of droplets from breathing, talking, or coughing. N95 and surgical masks are widely used in cleanroom environments.

3. Gowns and Coveralls

These full-body garments prevent human skin flakes, lint, and other particulates from contaminating pharmaceutical products. They are typically made from non-woven materials to reduce fiber shedding.

BODY PROTECTION PRODUCTS Information

4. Hair and Beard Covers

Hair and beard nets ensure that loose strands do not fall into the production environment, further reducing the risk of particulate contamination.

DISPOSABLE HYGIENE PRODUCTS Information

5. Foot Covers and Shoe Covers

Shoe covers prevent dirt, dust, and microorganisms from being tracked into cleanrooms, maintaining stringent hygiene levels.

DISPOSABLE HYGIENE PRODUCTS Information

6. Safety Goggles and Face Shields

Eye protection prevents accidental exposure to hazardous substances while also acting as a barrier to facial contamination.

EYE PROTECTION PRODUCTS Information

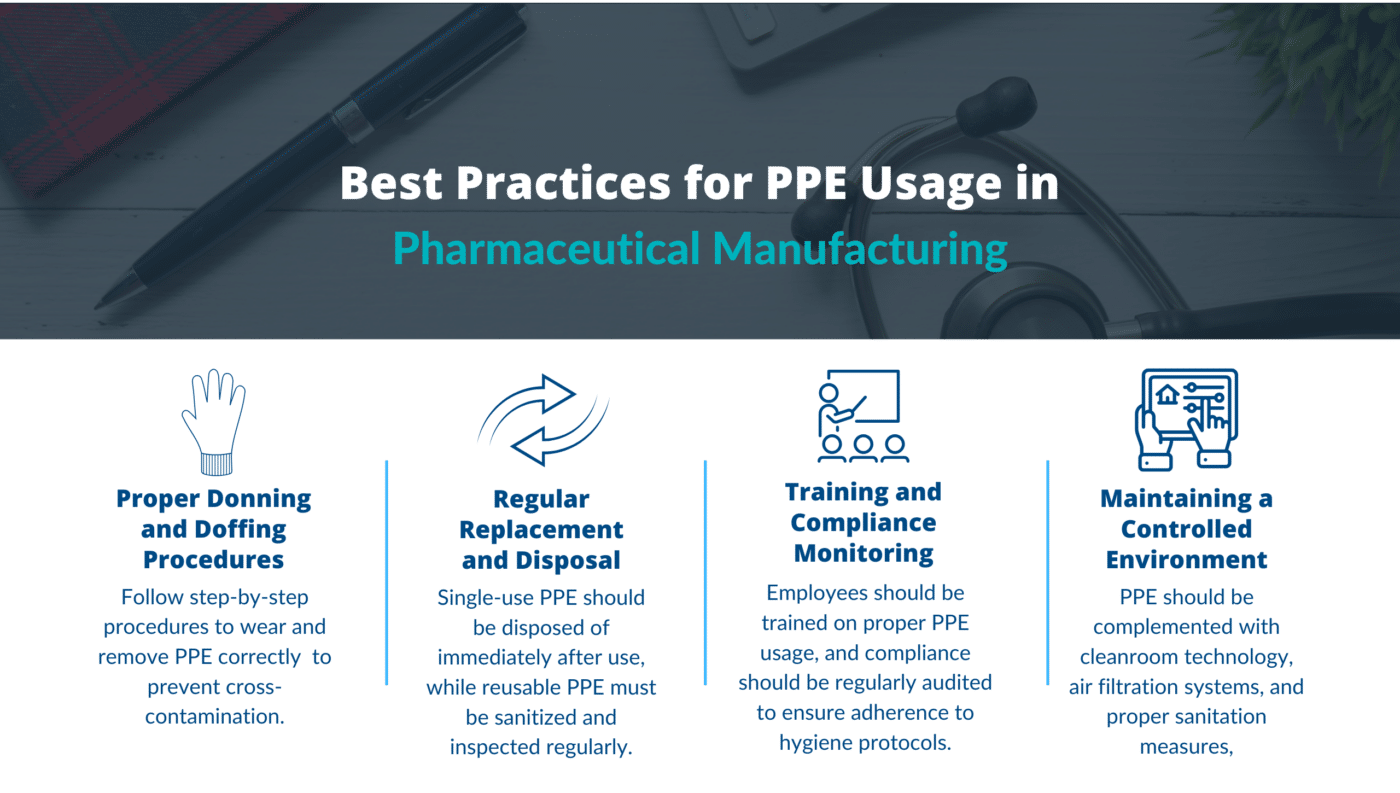

Best Practices for PPE Usage in Pharmaceutical Manufacturing

- Proper Donning and Doffing Procedures

- Employees must follow step-by-step procedures to wear and remove PPE correctly to prevent cross-contamination.

- Regular Replacement and Disposal

- Single-use PPE should be disposed of immediately after use, while reusable PPE must be sanitized and inspected regularly.

- Training and Compliance Monitoring

- Employees should be trained on proper PPE usage, and compliance should be regularly audited to ensure adherence to hygiene protocols.

- Maintaining a Controlled Environment

- PPE should be complemented with cleanroom technology, air filtration systems, and proper sanitation measures.

PPE is an essential component in pharmaceutical production to prevent contamination and maintain the integrity of medicines. By ensuring proper PPE selection, usage, and compliance, pharmaceutical companies can uphold the highest safety and hygiene standards. A well-implemented PPE program not only safeguards products but also protects workers and end consumers from potential health risks.

📞 Contact Us Now!

💻 Visit: www.safetyware.com

📧 Email: [email protected]

Stay Safe. Stay Compliant. Choose Safetyware!