What is PPE?

PPE (Personal Protective Equipment) refers to any item or device worn to protect the body from potential hazards. It includes protective clothing, helmets, goggles, face shields, respirators, gloves, earplugs, safety harnesses, and more. The main goal of PPE is to minimize exposure to workplace injuries or illnesses arising from chemical, biological, physical, electrical, mechanical, or other hazards.

Why is PPE Important?

-

Prevents Injuries: Effective use of safety goggles, protective gloves, and other PPE reduces the risk of cuts, bruises, or more severe injuries in high-risk environments such as construction sites, factories, or laboratories.

-

Protects Against Hazardous Substances: Respirators and face shields can protect against inhalation of toxic fumes, dust, or harmful particles, essential in industries like chemical manufacturing and pharmaceutical production.

-

Ensures Compliance With Regulations: Agencies such as Department of Occupational Safety and Health (DOSH) in Malaysia, Occupational Safety and Health Division (OSHD) under MOM in Singapore, and OSHA (Occupational Safety and Health Administration) in the United States require employers to provide adequate PPE. Compliance with these regulations not only protects workers but also avoids hefty fines and penalties.

-

Promotes a Safety Culture: When employees see their organization investing in high-quality PPE, it fosters a sense of care and responsibility, leading to better morale and productivity.

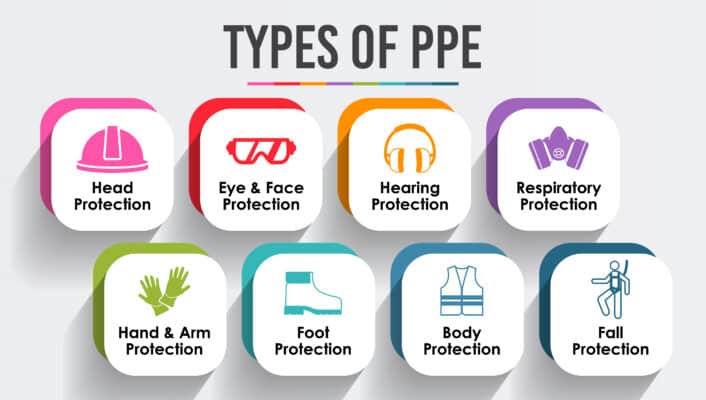

Types of PPE

Below are some of the most common PPE categories and examples of their uses:

-

Head Protection

- Hard Hats or Safety Helmets to shield against falling objects or head injuries.

- Bump Caps for environments with lower risk of head injuries.

-

Eye and Face Protection

- Safety Goggles and Face Shields to protect eyes and face from flying debris, chemical splashes, or bright light.

- Welding Helmets for high-intensity light during welding operations.

-

Hearing Protection

- Earplugs and Earmuffs reduce noise exposure and prevent hearing loss in noisy settings such as construction, airports, or music venues.

-

Respiratory Protection

- Dust Masks and Respirators (e.g., N95 respirators) filter out contaminants in the air.

- Full-Face Respirators for more hazardous or toxic environments.

-

Hand and Arm Protection

- Protective Gloves made of rubber, leather, or specialized materials to guard against chemicals, abrasions, or cuts.

- Arm Guards for extra protection in high-risk tasks involving sharp tools or chemicals.

-

Foot Protection

- Safety Boots or Steel-Toe Boots to shield feet from heavy falling objects, slippery surfaces, or electrical hazards.

- Slip-Resistant Footwear for added traction in wet or oily conditions.

-

Body Protection

- Coveralls, Aprons, Chemical Resistant Suits, and High-Visibility Clothing to prevent spills, burns, or accidents, especially in industrial environments.

- Flame-Resistant Clothing for workers exposed to fire hazards.

-

Fall Protection

- Harnesses, Lanyards, and Anchorage Systems designed to prevent or arrest falls from heights, often used in construction, roofing, or firefighting.

When Should You Use PPE?

- During High-Risk Tasks: Anyone working in construction, manufacturing, healthcare, laboratories, or any hazardous environment should wear appropriate PPE.

- Compliance with Workplace Rules: Employers often have PPE guidelines or regulations in place. Always follow these rules to avoid accidents and remain compliant.

- Preventative Measures: Even if a task seems low-risk, wearing basic PPE like gloves or goggles can help prevent unforeseen injuries.

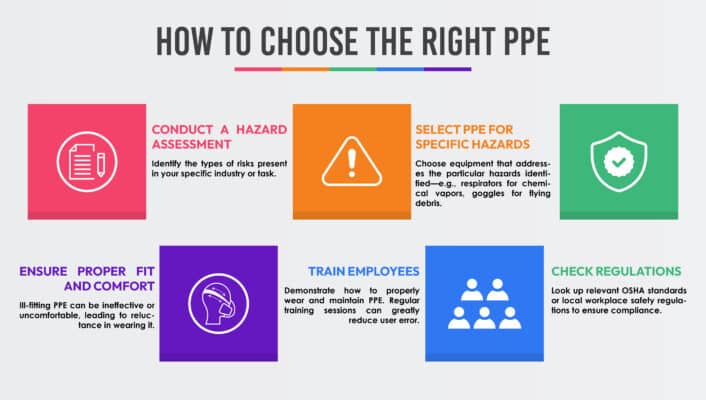

How to Choose the Right PPE

- Conduct a Hazard Assessment: Identify the types of risks present in your specific industry or task.

- Select PPE for Specific Hazards: Choose equipment that addresses the particular hazards identified—e.g., respirators for chemical vapors, goggles for flying debris.

- Check Regulations: Look up relevant OSHA standards or local workplace safety regulations to ensure compliance.

- Ensure Proper Fit and Comfort: Ill-fitting PPE can be ineffective or uncomfortable, leading to reluctance in wearing it.

- Train Employees: Demonstrate how to properly wear and maintain PPE. Regular training sessions can greatly reduce user error.

Maintenance and Care of PPE

- Regular Inspection: Look for signs of wear or damage such as holes, cracks, or loose parts before each use.

- Cleaning: Follow the manufacturer’s instructions for cleaning, especially for respirators, face shields, or chemical-resistant gloves.

- Proper Storage: Store PPE in a clean, dry area away from direct sunlight or corrosive substances.

- Scheduled Replacement: Even the best PPE has a lifespan. Replace items according to recommended schedules or as soon as damage is detected.

Common Myths About PPE

-

“Wearing PPE alone guarantees safety.”

- Fact: While crucial, PPE is only one part of a comprehensive safety plan that includes training, hazard controls, and proper procedures.

-

“PPE is too expensive for smaller businesses.”

- Fact: Investing in PPE can save costs in the long run by preventing accidents, injuries, and potential lawsuits.

-

“Only people in dangerous industries need PPE.”

- Fact: Even office environments may require PPE for certain tasks like handling cleaning chemicals or repairing electrical equipment.

Conclusion and Next Steps

Personal Protective Equipment (PPE) is essential to maintain a safe and compliant work environment. Whether you’re looking for construction PPE, healthcare PPE, or specialized industrial safety gear, choosing the right equipment can significantly reduce the risk of workplace injuries or illnesses. By understanding the different types of PPE, assessing workplace hazards, and following proper safety protocols, you’ll be well on your way to creating a culture of safety and responsibility.

Looking for more information or need help finding the right PPE solutions?

Browse our website or get in touch with our team of experts. We’re here to help you select the best PPE for your specific needs, ensuring you stay safe, compliant, and productive.