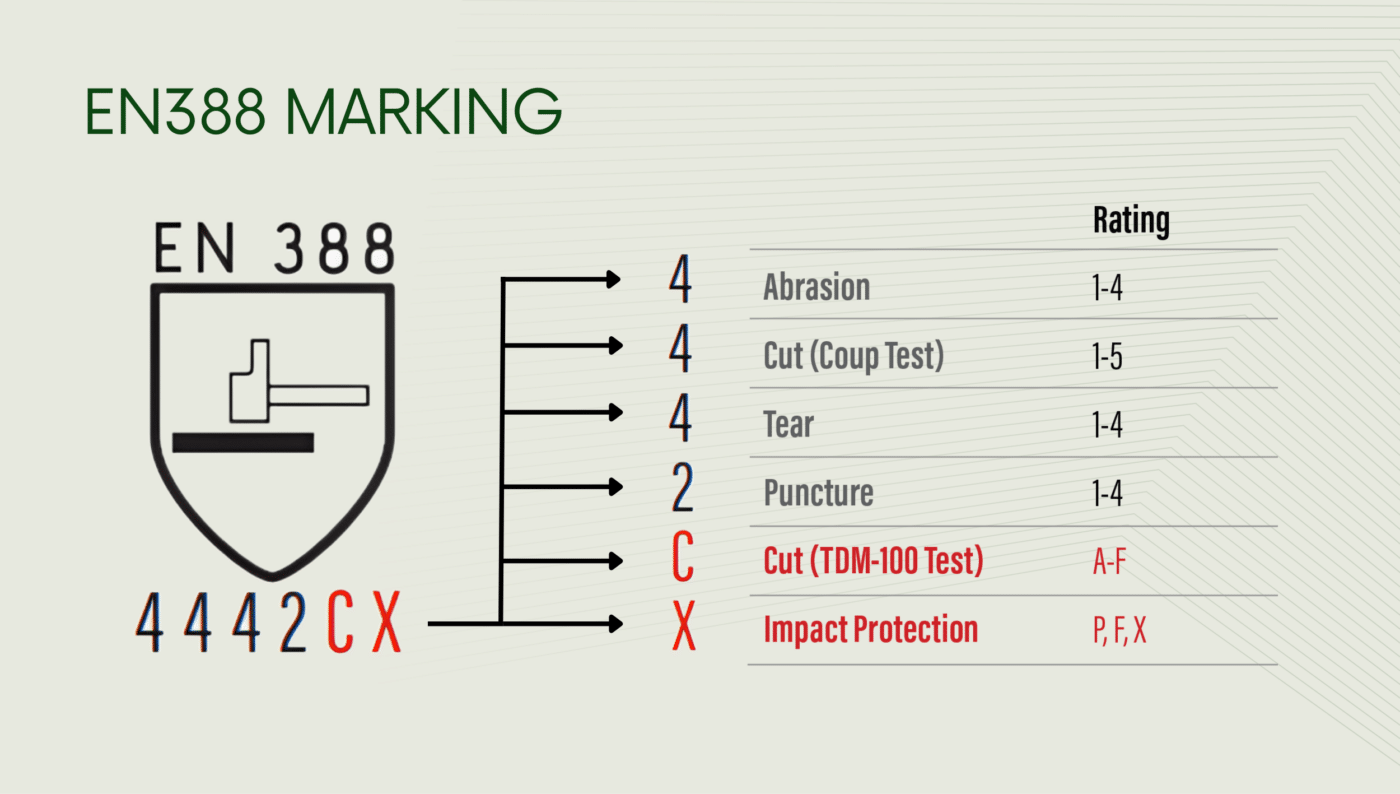

Key Changes in EN388:2016

1. Introduction of the TDM-100 Test for Cut Resistance

Before 2016, the Coup Test was the only method used to evaluate a glove’s cut resistance. While this test was effective for some applications, it had limitations, especially when dealing with high-performance fibers or materials that dull the testing blade.

The 2016 update introduced the TDM-100 Test (based on the ISO 13997 standard) to address these limitations. The combination of both tests provides a more accurate assessment of a glove’s cut resistance.

2. Impact Protection Test

The updated standard also introduced an Impact Protection Test to measure a glove’s ability to withstand impacts. Gloves that pass this test are marked with a “P” on their labeling, indicating compliance with the impact protection requirement.

Understanding the Test Methods for Cut Resistance

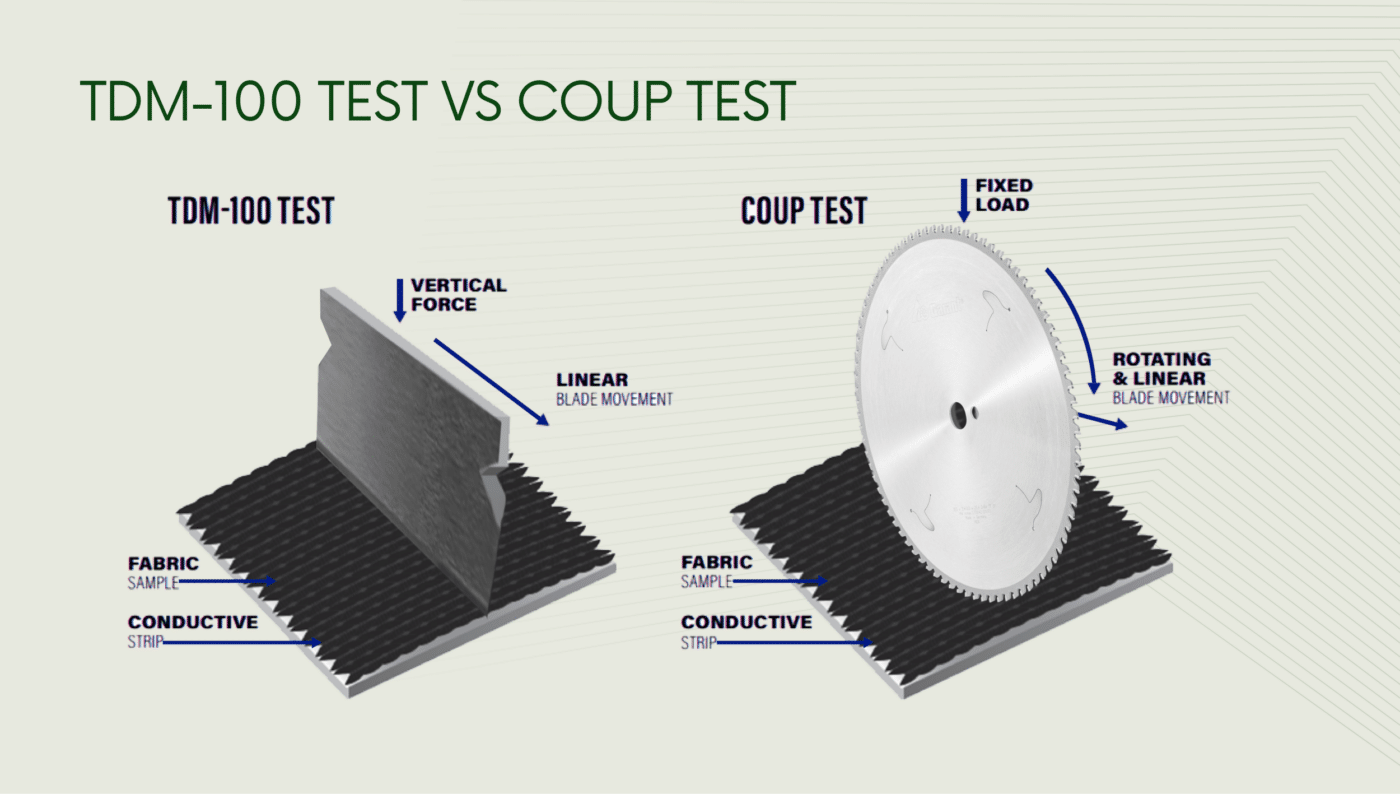

The Coup Test

The Coup Test evaluates a glove’s resistance to cutting using a circular blade. The blade moves back and forth across the glove material under a constant weight. The result is a cut index, which measures how many cycles the glove can withstand before being cut through.

Limitations: The Coup Test may provide unreliable results when testing gloves made of high-strength materials like aramids or steel fibers. These materials can dull the blade, leading to inconsistencies.

The TDM-100 Test (ISO 13997 Method)

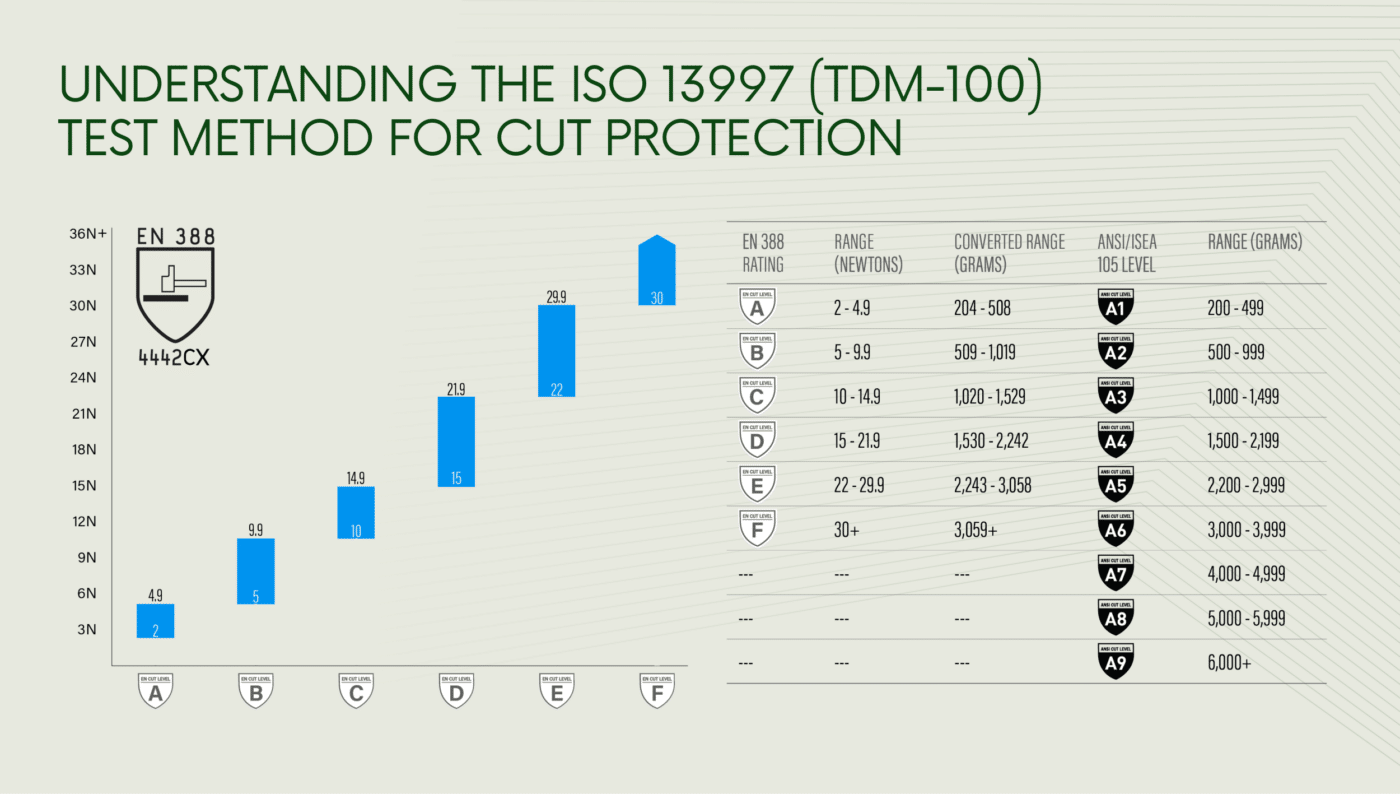

The TDM-100 Test provides a more precise measure of cut resistance, especially for advanced materials. In this test, a straight blade is used to cut through the glove material. The force required to achieve the cut is measured in newtons (N). The results are categorized into the following levels:

| Cut Resistance Level | Force (N) |

|---|---|

| A | ≤2 |

| B | >2 to ≤5 |

| C | >5 to ≤10 |

| D | >10 to ≤15 |

| E | >15 to ≤22 |

| F | >22 |

Understanding the ISO 13997 (TDM-100) Test Method for Cut Protection

The ISO 13997 method is widely regarded as the gold standard for assessing cut resistance. Here’s how it works:

- Straight Blade Application: A straight blade, rather than a circular one, is used.

- Variable Force Measurement: The test measures the force required to cut through the material in a single pass.

- Consistent Results Across Materials: Unlike the Coup Test, the TDM-100 test provides reliable results for high-strength materials, ensuring an accurate representation of cut resistance.

This test is especially critical for industries where workers handle sharp objects or high-risk materials, such as glass manufacturing, metal fabrication, and automotive assembly.

Additional Enhancements: Impact Protection

The EN388:2016 standard introduced a dedicated test to evaluate gloves’ ability to withstand impacts. This test is optional and applies to gloves designed with specific impact protection zones (e.g., on the knuckles). If the gloves pass, they are marked with a “P” under the EN388 score.

Why These Updates Matter

The updates to the EN388 standard provide several advantages:

- Enhanced Accuracy: The TDM-100 test ensures more reliable results for high-performance materials.

- Increased Safety: The introduction of impact protection testing helps industries where impact hazards are common.

- Improved Decision-Making: Buyers can make more informed choices when selecting gloves for specific tasks.

The updates to the EN388:2016 standard reflect advancements in glove technology and the need for precise, reliable safety measures. By combining the Coup Test, TDM-100 Test, and optional Impact Protection Test, this standard ensures comprehensive protection for workers across various industries.

Understanding these updates will help you choose gloves that meet the specific safety requirements of your workplace. Invest in EN388:2016-certified gloves to ensure maximum protection and peace of mind.

Safetyware Gloves: Your Trusted Hand Protection Partner

Safetyware offers a comprehensive range of EN388:2016-certified gloves designed to meet the highest safety standards. Our gloves provide:

- Exceptional Cut Resistance: Tested with both Coup and TDM-100 methods for accuracy.

- Durability and Comfort: Made from premium materials to ensure long-lasting performance and comfort.

- Versatility: Suitable for various industries including automotive, construction, and warehousing.

- Impact Protection: Selected models feature enhanced knuckle protection for added safety.

- Wide Range of Options: Explore our extensive hand protection catalog to find gloves tailored to your specific needs.

Discover the full range of Safetyware gloves by visiting our Hand Protection Catalogue. Equip your workforce with the best in safety and performance.

📞 Contact Us Now!

💻 Visit: www.safetyware.com

📧 Email: [email protected]

Stay Safe. Stay Compliant. Choose Safetyware!