From healthcare to heavy industry, gloves are essential for safeguarding hands against hazards like chemicals, cuts, heat, and electrical shocks. With diverse workplace risks, selecting the right glove type is critical. Drawing from Safetyware’s 2024 Hand Protection Catalogue, this guide breaks down Types of Gloves, their applications, and how Safetyware’s innovations meet global safety standards.

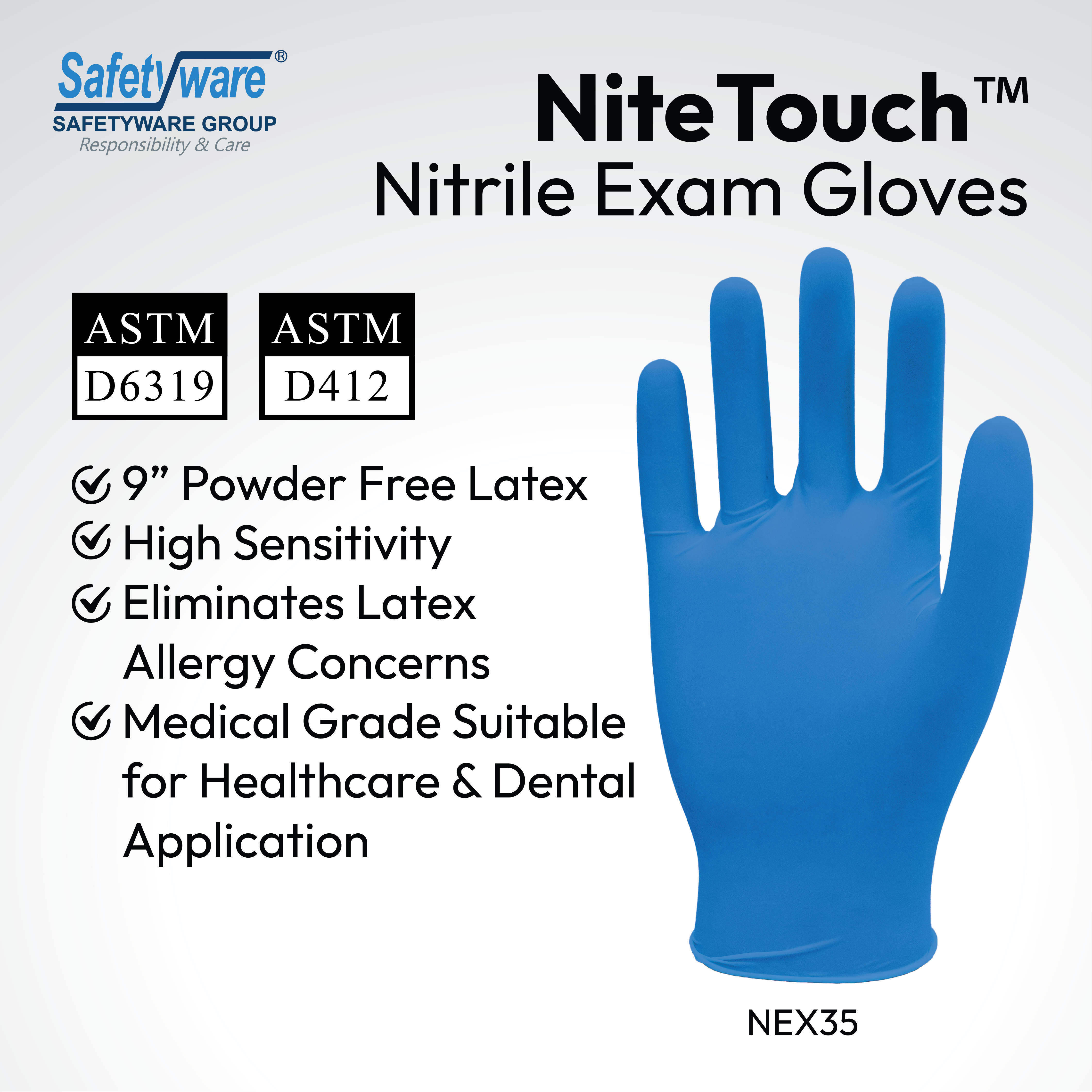

1. Disposable Gloves: Hygiene and Single-Use Protection

Disposable gloves are vital in medical, laboratory, and food processing environments for contamination control. Safetyware offers:

- Nitrile Gloves: Latex-free, puncture-resistant, and chemical-proof. NiteTouch™ NEX35 (3.5g) provides tactile sensitivity for medical exams, while NiteMax™ NEX100 (10g) offers heavy-duty protection for industrial cleaning.

- Latex Gloves: Elastic and biodegradable. Latex Touch™ LEX55 meets ASTM standards for surgical precision.

- Vinyl/PE Gloves: Budget-friendly for light tasks. EcoLite™ HDPE gloves are FDA-compliant for food handling.

- EcoGuard™ BioSeries: Biodegradable nitrile gloves that decompose 90% faster, aligning with sustainability goals.

Best for: Healthcare, food safety, and low-risk chemical handling.

2. Industrial and Chemical-Resistant Gloves

For harsh environments involving chemicals, oils, or solvents:

- Natural Rubber Gloves: GenPlus™ PF1712 resists animal fats and mild acids, ideal for food processing.

- Nitrile Blends: ChemMax™ CMX26L (660mm length) protects against abrasion and chemicals like oils and acids, compliant with EN374.

- Neoprene Gloves: Duoprene™ BC2113 blends neoprene and rubber for superior chemical resistance (e.g., alcohols, peroxides).

- PVC Gloves: Protecto™ VDR35S shields against acids and oils in automotive or painting tasks.

Key Feature: Safetyware’s S-Grip™ coating enhances waterproofing and grip in oily conditions.

3. Cut-Resistant and Anti-Impact Gloves

Designed for sharp objects, blades, or machinery:

- HPPE-Blend Gloves: UltraCut™ ULS03 (EN388 Level F) uses 18-gauge HPPE with double nitrile coating for glass handling.

- Stainless Steel Mesh: BladeArmor™ SS500 (AISI 304L steel) offers 200N tensile strength for meat processing or metalwork.

- Anti-Impact Gloves: ImpactGuard™ combines sandy nitrile palms with EN388 Level F cut resistance for construction and machinery.

Innovation: Honeymesh™ knitting technology in SensiCut™ gloves improves breathability and dexterity for precision tasks.

4. Thermal Protection Gloves

For extreme temperatures:

- Heat Resistance: ThermoGard™ HRG03 (500°C resistance) uses para-aramid felt and aluminized backing for welding.

- Cold Resistance: FrostArmor™ CRG02 (-25°C) features double rubber insulation for cold storage or outdoor work.

- Cryogenic Gloves: CryoArmor™ CRG58 (580mm length) protects against -250°C for LNG handling and labs.

Certification: EN407 (heat) and EN511 (cold) compliance ensure tested performance.

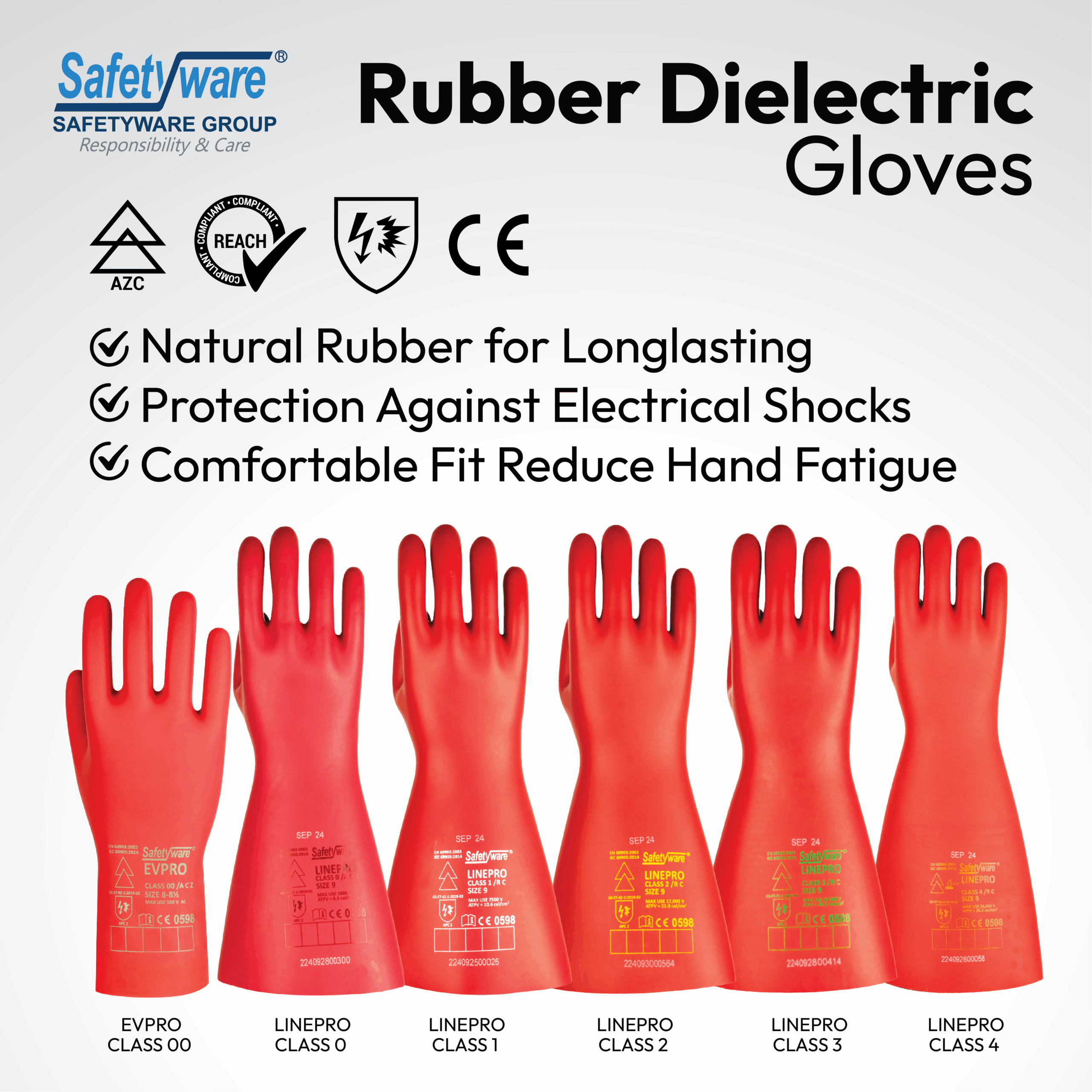

5. Electrical Insulating Gloves

For live electrical work:

- VoltShield™ Dielectric Gloves: Class 00 (500V) to Class 4 (36,000V) options, made from ozone-resistant natural rubber.

- Features: Bright orange for visibility, EN60903 certified, and acid/ozone resistant.

Application: Electricians, utility workers, and telecom engineers.

6. Specialized Gloves

- ESD Gloves: *FlexiPlus-ESD™ FP200* dissipates static for electronics manufacturing.

- Welding Gloves: LG203 combines goat leather (sensitivity) and cow split leather (durability) for TIG welding.

- Food-Safe Gloves: GenPlus™ PF1712 complies with FDA and EU food contact regulations.

How to Choose the Right Types of Gloves

- Assess Hazards: Identify chemicals, temperatures, or physical risks.

- Check Certifications: Look for EN, ASTM, or FDA compliance.

- Prioritize Fit: Safetyware’s sizing chart ensures ergonomic comfort.

- Consider Durability: Reusable options like NitraGuard™ NBR03 reduce long-term costs.

Why Choose Safetyware?

- 40+ Years of Expertise: Rooted in Malaysian rubber manufacturing since 1983.

- Global Compliance: Meets EN, ANSI, and ISO standards.

- Sustainability Focus: Biodegradable and recyclable options like EcoGuard™.

- Custom Solutions: From touchscreen-compatible XtraFlex™ to cryogenic sleeves.

Explore Safetyware’s Range:

Whether you need cut-resistant UltraCut™ gloves for glass handling or chemical-proof ChemMax™ sleeves for labs, Safetyware combines innovation with reliability. Visit Safetyware’s website to download the full catalogue or request a consultation.

Protect Your Hands—Trust Safetyware. 🧤🛡️

Any Questions? Contact Us:

📩 Email: [email protected]

🌐 Website: www.safetyware.com

📞 Contact us: WhatsApp