Head injuries account for a significant percentage of workplace fatalities and permanent disabilities worldwide. Industrial safety helmets are not just another piece of PPE—they’re your first line of defense against falling objects, electrical hazards, and impact injuries. This comprehensive FAQ guide answers all your questions about choosing, using, and maintaining the right safety helmet for your work environment.

1. Understanding Helmet Types: Which One Do You Need?

Not all safety helmets are created equal. The right choice depends entirely on your work environment and specific hazards:

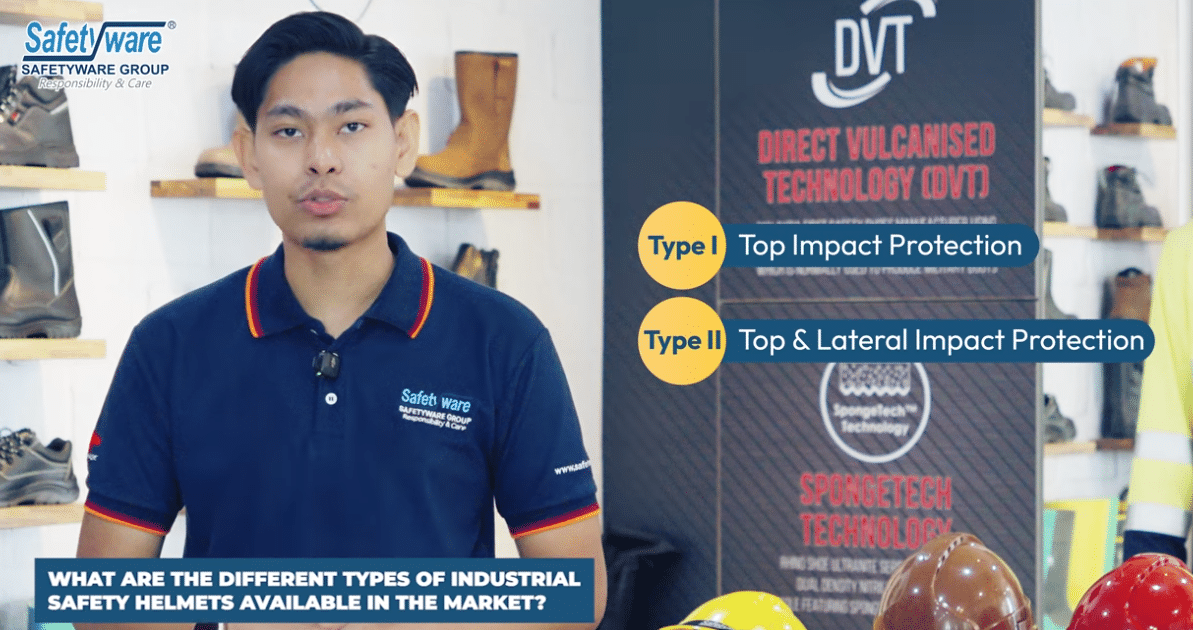

Type I vs. Type II Helmets

| Feature | Type I Helmets | Type II Helmets |

|---|---|---|

| Protection | Top impact only | Top and lateral/side impact |

| Standards | Basic ANSI/ISEA Z89.1, EN 397 | Enhanced protection standards |

| Best For | General construction, warehouses | Mining, forestry, high-risk industries |

Vented vs. Non-Vented Helmets

- Vented Helmets: Perfect for hot environments (construction sites, outdoor work) where airflow is crucial

- Non-Vented Helmets: Essential for electrical work, chemical handling, and confined spaces where maximum protection is needed

Key Takeaway: Match your helmet to your hazards—vented for comfort in low-risk hot environments, non-vented for high-risk scenarios.

2. Safety Standards: What Do They Mean?

Industrial helmets must comply with international standards to ensure adequate protection:

- ANSI/ISEA Z89.1 (North America): Classifies helmets by type and electrical protection

- EN 397 (Europe): Specifies impact, penetration, and flame resistance requirements

- CSA Z94.1 (Canada): Similar to ANSI with additional Canadian requirements

- AS/NZS 1801 (Australia/New Zealand): Includes unique testing for UV resistance

Always check for certification marks inside the helmet shell before use.

3. Helmet Lifespan: When to Replace Your Protection

Safety helmets don’t last forever. Their lifespan depends on multiple factors:

- Shelf Life: 5-7 years from manufacture date (unused and properly stored)

- Service Life: Varies based on:

- Sunlight exposure (UV degradation)

- Temperature extremes

- Chemical contact

- Impact history

- General wear and tear

Pro Tip: Write the purchase date inside your helmet with permanent marker to track its age.

4. Helmet Color Coding: More Than Just Fashion

Color coding enhances worksite communication and safety:

| Color | Typical Role | Industry |

|---|---|---|

| White | Managers, supervisors, engineers | All industries |

| Yellow | General laborers, earth-moving operators | Construction, logistics |

| Blue | Carpenters, electricians, technicians | Construction, manufacturing |

| Green | Safety officers, new workers | All industries |

| Red | Firefighters, emergency responders | Emergency services, oil & gas |

| Orange | Road crews, lifting operators | Roadwork, crane operations |

5. Maintenance and Inspection: Protecting Your Protection

Proper care extends your helmet’s life and ensures optimal performance:

Daily Inspection Checklist

- Cracks, dents, or signs of impact damage

- Fading or chalky appearance (indicates UV damage)

- Secure suspension system and chin strap

- Clean shell free of chemicals or debris

Cleaning and Storage

- Clean with mild soap and water—avoid solvents

- Store away from direct sunlight and extreme temperatures

- Never modify or drill holes in the helmet shell

- Replace after any significant impact, even if no damage is visible

6. Critical Warning: Motorcycle Helmets Don’t Belong on Worksites

Motorcycle helmets are NOT substitutes for industrial safety helmets. They differ in:

- Impact Standards: Designed for different impact velocities and angles

- Weight and Design: Heavier and less suitable for all-day wear

- Peripheral Vision: Often restricts side vision needed for worksite awareness

- Electrical Protection: May not offer the same dielectric properties

7. Consequences of Not Wearing Proper Head Protection

The risks go beyond potential injuries:

- Severe Injury: Head trauma from falling objects or impacts

- Legal Penalties: Fines and citations from OSHA and other regulators

- Disciplinary Action: Violation of company safety policies

- Increased Insurance Costs: Workplace incidents raise premiums

Remember: The few seconds it takes to put on a helmet could save your life.

Safetyware’s Helmet Solutions: Engineered for Protection

Safetyware offers a comprehensive range of certified safety helmets including:

- Vanguard Vented Series: For hot weather comfort with full protection

- TitanShield Non-Vented: Maximum protection for high-risk environments

- Electrical Hazard Rated: For utility and electrical workers

- Custom Color Programs: Role-specific coloring for your organization

Conclusion: Your Head Deserves the Best Protection

Choosing and properly maintaining your safety helmet is one of the most important safety decisions you’ll make. From understanding standards to recognizing when to replace your helmet, these guidelines ensure you stay protected in any work environment.

Don’t just wear a helmet—wear the RIGHT helmet for the job.

Learn more from SAFETYWARE FAQ by clicking HERE!

If you need a quotation, feel free to contact us at:

📩 Email: [email protected]

📞 Tel: WhatsApp Us