| Brand | Safetyware |

|---|---|

| Color | Blue, Red |

| Protection Type | Heat & Flame Resistant |

| Size | 559mm(L) , 254mm(H) , 280mm(W) |

| Unit of Measurement | Piece |

FAQs

Body Protection

No, not all antistatic materials are ESD-safe. Antistatic products prevent static buildup but may not control or safely discharge static, which is crucial in ESD-sensitive environments.

Limited-use chemical protective coveralls are typically not designed for cleaning or decontamination. They should be disposed of immediately after use to prevent cross-contamination. Follow your organization’s waste disposal guidelines for hazardous materials.

Yes, there are different types of ESD & Cleanroom apparel for different categories of industries. The specific requirements for protection against electrostatic discharge (ESD) and particulate contamination can vary depending on the category of industry, such as:

Medical Devices: In this industry, cleanroom garments and gowns are used to control particulate contamination in the manufacturing of medical devices.

Pharmaceuticals: In this industry, cleanroom garments and gowns are commonly used to control particulate contamination in the manufacturing of drugs and medical devices.

Semiconductor: In this industry, ESD-safe clothing and cleanroom garments are used to protect against electrostatic discharge and particulate contamination in the manufacturing of electronic components.

Aerospace: In this industry, cleanroom garments and protective clothing are used to protect against particulate contamination and hazardous materials in the manufacturing and maintenance of aircraft and spacecraft.

Yes, our ESD cleanroom apparel is designed to be worn with other PPE such as ESD shoes, gloves, and face masks, providing full protection in static-sensitive environments.

Yes, antistatic and ESD materials can be used together for layered protection, especially in environments where both static prevention and safe discharge are important.

Yes, FR apparel can be worn with other PPE, such as hard hats, gloves, and eye protection, to ensure comprehensive protection in hazardous work environments.

It is recommended to use a laundry detergent specifically designed for high visibility safety clothing. These detergents are formulated to clean the reflective material without damaging it, ensuring that the clothing maintains its visibility and safety properties. Avoid using bleach or fabric softeners, as they can damage the reflective material.

It is possible to wear ESD & Cleanroom apparel over regular clothing, but it is not always recommended. Wearing additional layers under the ESD & Cleanroom apparel may affect the fit and reduce the effectiveness of the clothing in protecting against electrostatic discharge and particulate contamination.

In a cleanroom environment, it is important to wear only the designated cleanroom attire to avoid introducing contaminants from outside clothing. In an ESD-sensitive environment, wearing additional layers can also increase the risk of generating static electricity and causing electrostatic discharge.

Yes, OTÉGO aluminized apparel is designed to work seamlessly with other PPE, such as heat-resistant gloves, helmets, and face shields, for complete protection in hazardous environments

Yes, our ESD cleanroom apparel is designed for reuse. They are durable and can be washed and sterilized according to cleanroom protocols without losing their ESD properties.

Most ULTITEC garments are designed for single-use to avoid contamination. Reusing them may compromise their protective properties, especially after exposure to hazardous substances.

Yes, we offer custom printing options for logos, company names, and job titles on our high visibility vests, making them ideal for team identification.

Yes, we provide custom sizing and logo printing options for our ESD apparel to meet your company’s specific needs for branding and identification.

Yes, Safetyware provides training on how to properly don, doff, and dispose of ULTITEC protective clothing to ensure maximum protection and compliance with safety protocols.

Yes, Safetyware provides bulk ordering options for high visibility vests, ensuring businesses can outfit entire teams with compliant safety gear.

Yes, we offer custom sizing and logo printing for FR apparel, ensuring a proper fit and allowing businesses to brand their protective clothing.

Yes, ULTITEC protective clothing, particularly those certified to EN 14126, is suitable for healthcare workers and others exposed to infectious agents, including COVID-19.

Regularly inspect the coverall for signs of damage such as tears, punctures, or chemical degradation. Look for any discoloration or weakening of the material. If you find any damage, discard the coverall immediately and replace it with a new one.

Antistatic materials reduce the likelihood of static electricity by minimizing friction or by conducting small amounts of charge away before it accumulates to a dangerous level.

ESD materials are designed to dissipate static electricity safely to the ground, preventing harmful discharges that can damage sensitive components or ignite flammable substances.

The choice depends on the potential hazards in your environment. For areas with chemical handling, a combination unit with both an eye wash and shower may be necessary. Portable units are ideal for remote or temporary locations.

The best way to clean a high visibility safety vest is to follow the manufacturer’s care instructions. This may include machine washing or hand washing in cold water and hanging to dry.

If you work with sensitive electronics, flammable materials, or in cleanroom environments, ESD protection is crucial. For environments with lower static risk, antistatic materials are generally sufficient.

The effectiveness of FR clothing can be impacted by a number of factors, including wear and tear, exposure to chemicals, and improper washing. To determine if your FR clothing is still effective, it is recommended to have it tested by a qualified professional or to follow the manufacturer’s recommendations for inspection and replacement.

The best way to determine the correct size is to take your body measurements and compare them to the size chart provided by the manufacturer.

The choice of limited-use chemicalcoverall depends on the specific hazards you face. Consider the type of chemicals you’ll be handling, their form (liquid, solid, aerosol), and the potential for exposure. Consulting a safety professional for a risk assessment can help determine the appropriate level of protection.

You may find the selection chart on https://ultitec-protection.com/selecting-chart/

The aluminized layer in the apparel reflects a significant portion of radiant heat away from the wearer, reducing heat absorption and protecting against thermal hazards.

FR clothing is made from specially treated fabrics that resist igniting and are designed to self-extinguish when exposed to flames, limiting the spread of fire and preventing severe burns.

The lifespan of a limited-use chemical protective coveralls can vary depending on the specific material, the type of chemicals it’s exposed to, and the conditions under which it’s used. Generally, these coveralls are designed for single use. Factors that can shorten their lifespan include punctures, tears, chemical degradation, and exposure to excessive heat or cold.

In case of chemical exposure, the affected area should be flushed for at least 15 minutes to ensure thorough decontamination, according to safety guidelines.

Safetyware recommends testing emergency eye wash and shower units weekly to ensure proper operation. Annual inspections should also be conducted to verify compliance with safety standards.

The lifespan of a high visibility safety vest depends on the frequency of use and the level of care it receives. It is recommended to replace your vest if it shows signs of wear and tear, such as frayed edges or faded reflective material.

In general, FR clothing should be washed after each use to remove dirt, grime, and other contaminants that can affect its flame-resistant properties. It’s important to follow the manufacturer’s care instructions, as different FR fabrics may have different care requirements.

In some cases, FR clothing may be able to be worn multiple times before washing, but this will depend on the conditions in which it is being worn and the specific type of FR fabric used. If the FR clothing becomes soiled or shows signs of wear and tear, it should be washed and replaced as necessary.

It is recommended to wash your high visibility safety clothing after every wear, especially if it has been exposed to dirt, dust, or other contaminants. The reflective material on the clothing can become less effective if it is not kept clean, so it’s important to wash it regularly to ensure maximum visibility and safety.

ESD garments should be washed according to manufacturer instructions in specialized cleanroom laundry facilities. Use non-ionic detergents and avoid bleach or fabric softeners to preserve ESD properties.

ULTITEC garments should be stored in a cool, dry place, away from direct sunlight and chemicals, to maintain their protective properties. Always check the manufacturer’s instructions for proper storage guidelines.

For optimal performance and longevity, store your ULTITEC coveralls in a cool, dry place away from direct sunlight, high temperatures, and solvent vapors. Ideally, store them within a temperature range of 15°C to +25°C (58°F to 78°F) and with relative humidity below 80%.

According to EU regulations, ULTITEC coveralls are designed for single use. However, the decision to reuse them ultimately rests with the user. If you choose to reuse a coverall, exercise extreme caution during donning and doffing to avoid contamination.

Yes, OTÉGO aluminized apparel complies with international safety standards like EN ISO 11612 for heat and flame resistance, ensuring protection in extreme temperature environments.

Yes, ULTITEC garments are certified to international safety standards, including EN 14126 for protection against biological hazards, EN 14605 for liquid-tight protection, and they are also approved by SIRIM-DOSH for use in hazardous environments in Malaysia.

Common mistakes include improper donning and doffing, not selecting the right type of coverall for the specific hazard, reusing disposable coveralls, and not inspecting the coverall for damage before use. mistakes include improper donning and doffing, not selecting the right type of coverall for the specific hazard, reusing disposable coveralls, and not inspecting the coverall for damage before use.

Class 1 vests are for low-risk environments, offering basic visibility. Class 2 vests provide better visibility and are used in moderate-risk environments. Class 3 vests offer the highest visibility and are required in high-risk environments, such as construction zones or highways.

OSHA and ANSI mandate that eyewash units maintain a flow rate of 0.4 gallons per minute, while showers must have a flow rate of 20 gallons per minute.

- Heat and flame resistance: Provides protection against extreme heat and open flames.

- Reflectivity: The aluminized surface reflects a significant portion of radiant heat.

- Durability: Made from materials designed to withstand harsh industrial environments.

- Comfort: Lightweight and breathable to ensure comfort during prolonged use.

While highly effective against radiant heat, aluminization apparel may have limitations in terms of chel resistance and should not be used in environments where chemical exposure is a primary hazard.

Safetyware’ s ESD and cleanroom apparel is available in a range of colors, including white, navy blue, sky blue, yellow, pink , and apple green.

CE certifications indicate that a chemical coverall meets specific European Union safety standards.

- Type 3: Protects against sprays of hazardous liquids.

- Type 4: Protects against penetration by hazardous liquids.

- Type 5-B: Protects against dry particulate aerosols.

- Type 6-B: Limited protection against sprays of hazardous liquids.

To choose the right size, we offer a variety of options based on chest size and height. You can find a detailed size chart on https://ultitec-protection.com/size-chart/

OTÉGO aluminized apparel is commonly used in industries such as metal smelting, welding, glass production, and foundries, where workers are regularly exposed to extreme temperatures and molten materials.

Industries such as oil and gas, electrical, firefighting, welding, and chemical processing commonly use FR apparel to protect workers from fire-related hazards and high-heat environments.

Our ESD garments are commonly used in industries like electronics manufacturing, pharmaceuticals, biotechnology, aerospace, and any environment that requires strict static and contamination control.

Chemical permeation is the process by which a chemical moves through a protective material at a molecular level.

It’s crucial to understand permeation because even if a chemical coverall appears undamaged, harmful chemicals can still pass through the material over time. This can lead to skin exposure and health risks. Therefore, choosing a coverall with high permeation resistance is essential for worker safety.

You may log on to the website link below by key in the chemical name / CAS number to select the right coverall

Cleanroom apparel is clothing designed to minimize contamination and protect against particulate matter in controlled environments. It is used in cleanrooms, laboratories, and other settings where sensitive processes and products are being handled.

OTÉGO aluminized apparel is protective clothing designed to reflect radiant heat, protect against molten metal splashes, and provide insulation in high-temperature environments like foundries and metalworking industries.

Antistatic materials reduce or inhibit the generation of static electricity, while ESD (Electrostatic Discharge) materials control and dissipate static charges safely to prevent damage to sensitive electronics or hazardous environments.

Smocks provide partial coverage, ideal for environments with lower contamination risks. Jumpsuits and coveralls offer full-body protection, suitable for high-risk cleanroom environments that require maximum contamination and static control.

The difference lies in the protection level:

- ULTITEC 2000 offers splash protection from low-hazard liquids.

- ULTITEC 3000 provides higher resistance to chemical sprays.

- ULTITEC 4000 offers the highest level of protection against hazardous chemicals and biological agents.

The lifespan varies based on usage, exposure to extreme conditions, and maintenance. Regular inspections and proper care can extend the lifespan of the apparel.

ULTITEC protective clothing is a range of high-performance garments designed to protect against hazardous chemicals, biological agents, and particulates. It is widely used in industries like healthcare, chemical handling, and hazardous waste management.

OTÉGO aluminized apparel is engineered to protect against radiant heat, contact heat, and molten metal splashes, making it suitable for environments with extreme heat hazards.

OTÉGO aluminized apparel is made from a combination of heat-resistant fabrics such as aramid fibers and a reflective aluminum coating that helps deflect radiant heat and molten metal.

Our ESD garments are made from lightweight, breathable polyester fabric with conductive fiber threads woven in to dissipate static charges safely.

Depending on the hazards, you may need additional PPE like gloves, boots, eye protection, and respiratory protection. Visit Safetyware for more information on additional personal protective equipment (PPE).

By combining FR and arc flash protection into a single garment, FR clothing with arc flash protection provides workers with comprehensive protection against both fire and heat hazards and electrical hazards. This type of clothing is often used in industries such as oil and gas, electrical utilities, and manufacturing, where workers may be exposed to both fire and heat hazards and electrical hazards.

Safetyware offers a range of ESD-safe cleanroom apparel, including smocks, jumpsuits, coveralls, and other garments designed to minimize static discharge in sensitive environments like electronics manufacturing and cleanrooms.

Safetyware offers a variety of FR apparel, including coveralls, jackets, trousers, shirts, and bib overalls, designed for industries like oil and gas, welding, electrical, and firefighting.

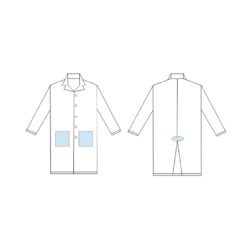

Safetyware offers a variety of ULTITEC protective suits, including coveralls, lab coats, and gowns, designed for different levels of protection, from basic splash protection to full-body chemical protection.

Flame-resistant (FR) clothing is made from materials that inherently resist ignition, while flame-retardant clothing is treated with chemicals to achieve fire resistance. Both provide protection, but FR garments are more durable over time.

FR clothing is designed to protect against fire and heat by preventing the clothing from igniting and spreading flames. FR clothing is typically made from materials that have been treated with fire-retardant chemicals or from fibers that have inherent flame-resistant properties.

Aluminized heat protection, on the other hand, is designed to protect against high heat and radiant heat. Aluminized clothing is made from materials that have been coated with a reflective material, such as aluminum, to reflect radiant heat away from the wearer.

If the primary hazard is fire, then FR clothing would be the best choice. If the primary hazard is radiant heat, then aluminized heat protection would be a better choice. In some cases, a combination of both FR clothing and aluminized heat protection may be necessary to provide adequate protection against both fire and radiant heat hazards.

Workers in high-risk industries like oil and gas, electrical utilities, welding, firefighting, and chemical processing should wear FR apparel to protect against flash fires, arc flashes, and other fire hazards.

Workers exposed to radiant heat, molten metals, or extreme temperatures, such as in foundries, welding operations, and glass manufacturing, should wear OTÉGO aluminized apparel for enhanced protection.

Workers in industries like healthcare, pharmaceuticals, chemical handling, industrial cleaning, and hazardous material handling should wear ULTITEC clothing to protect against hazardous substances and contamination.

FR products are important because they help to protect workers who are exposed to fire and heat-related hazards in the workplace. By providing a barrier between the worker and the hazard, FR products can help prevent burns, fires, and other heat-related injuries.

Related products

Body Protection

Body Protection

SAFETYWARE Cleanroom ESD Jacket Shirt Collar (0.5mm Stripe Line)

Body Protection

Arc Flash Protection

Body Protection

Arc Flash Protection