Respirators Vs Disposable Face Masks

Both respirators and disposable face masks are types of personal protective equipment (PPE) that are widely used to offer protection to wearer against contamination from hazardous substances airborne or liquid. Respirators particularly filters hazardous substances in the air like particulates, vapours, and gases while the disposable face masks filters potential contaminants (larger particles) in the immediate environment. Check out the differences as below:

| Respirators | Disposable Face Mask |

|---|---|

| Includes different types of respirators like particulate respirators, cartridge respirators, powered air-purifying respirators (PAPR) and self-contained breathing apparatus (SCBA) | Also known as procedural / surgical mask |

| Provide barrier against hazardous airborne substance such as particles, gases, or vapours (and even virus & bacteria) | Provide barrier against harmful splashes, droplets, or sprays of blood, body fluids, secretions, and excretions |

| Filter smaller particles (< 0.3 micron) | Filter larger particles (0.1 – 3 micron) |

| Respirators are tested, evaluated, and certified by Department of Occupational Safety and Health (DOSH) by SIRIM Malaysia to meet set minimum performance requirements, including filter efficiency and breathing resistance. | Disposable face masks are tested, evaluated and certified through the American Society of Testing and Materials (ASTM) and European Standard EN14683 on bacteria filtration efficiency (BFE), particle filtration efficiency (PFE), breathing resistant and splash resistance. |

| Designed to offers tight fitting - close fit to face | Not designed for tight fitting - loose fit to face. |

| Suitable for use with purpose to prevent occupational diseases caused by inhalation of contaminated air. | Suitable for general use to counter cross-contamination or prevent the spread of diseases. |

| For one-time usage only | For one-time usage only |

Why SAFETYWARE?

With more than 30 years of experience in Personal Protective Equipment (PPE) manufacturing, Safetyware assure each product is manufactured under stringent quality control systems certified to ISO 9001:2015 Standard. Our quality products are certified to CE, ANSI, AS/NZS, SIRIM, Singapore Standard, etc. and supported by a Strong R&D Team for continuous improvement on Product Quality.

Safetyware’s premium face masks meet ASTM F1862 & ISO 22609 and ASTM F2100 & EN 14683 standards. As for Safetyware’s particulate respirators, the product is tested, approved and certified under the SIRIM DOSH standards. We utilize the ultraviolet sterilisation process to ensure the highest hygiene standard for the entire category of products. Besides, our premium face mask employs ultrasonic welding technology to firm the bonding between mask and ties. The premium face masks also achieved customers’ high satisfaction with the good breathability feature and hypoallergenic materials. Undeniable, these are the key advantages of our products.

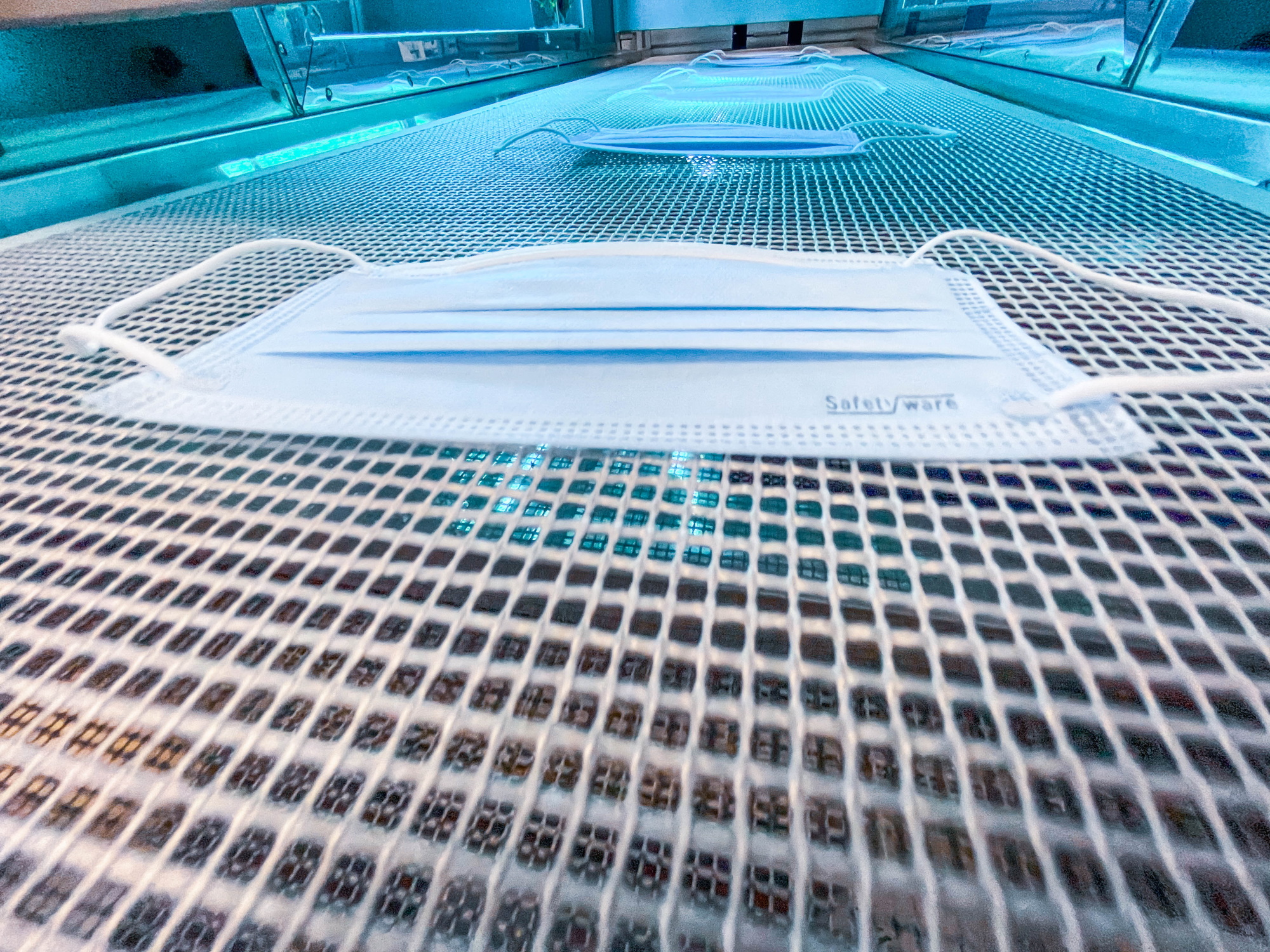

Ultraviolet Sterilisation

Face masks / particulate respirator are considered as one of the Personal Protection Equipment (PPE) that provide the protection of nose and mouth against dust, pollen, bacteria and so on. To ensure our face masks are at the highest hygiene standard and free of contamination, each piece of mask is ultraviolet (UV) sterilised after production and before packing process.

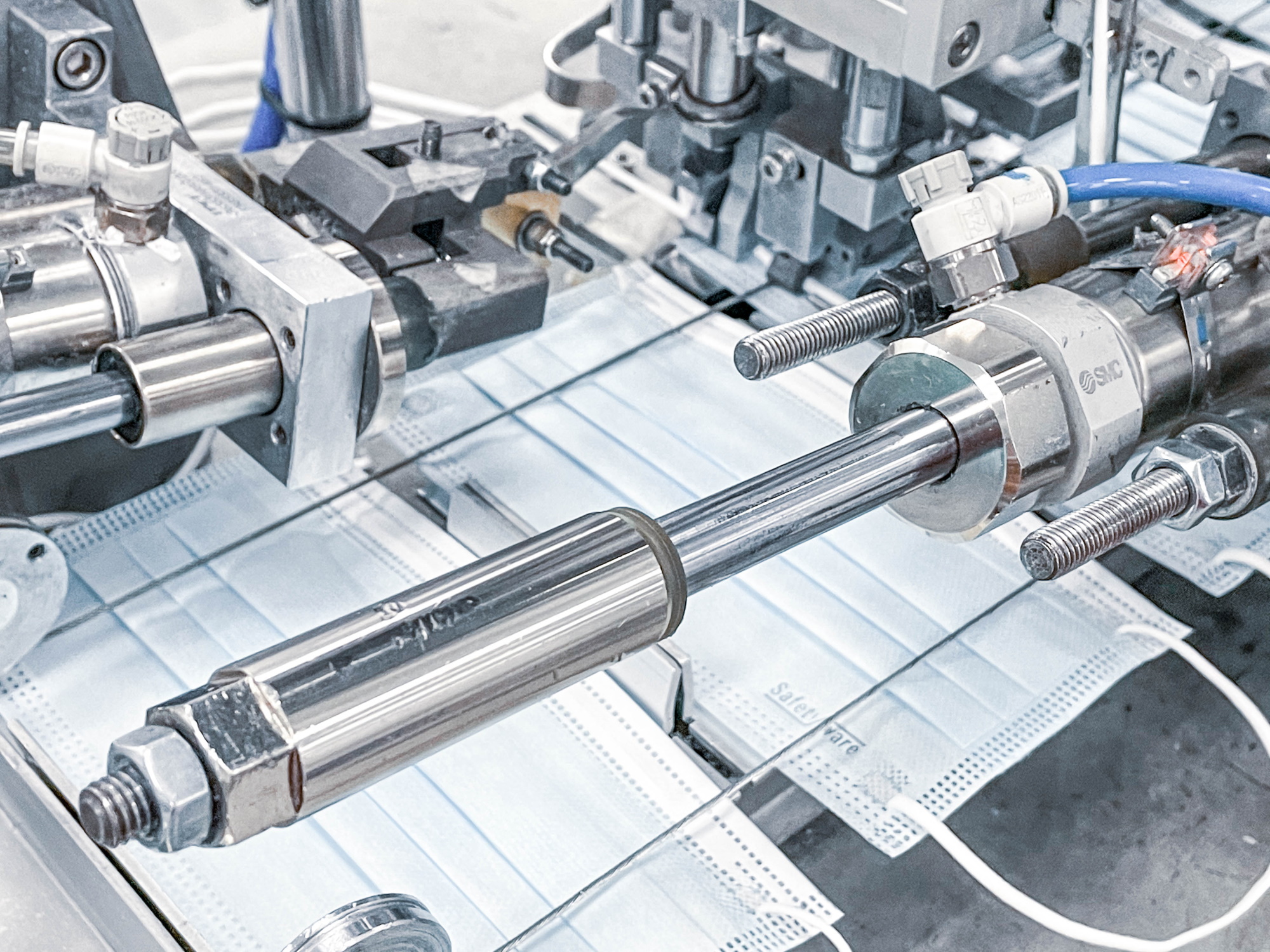

Ultrasonic Welding Technology

Safetyware’s face mask uses the Ultrasonic welding technology that is fast, clean, efficient and offers strong and integral bonds between the mask body and thread with no solvents, adhesives, mechanical fasteners, or external heat required. The finished face mask would be strong in bonding apart from the face mask hygiene standard.

Comfort

The hypoallergenic materials offer comfort and are suitable for all skin type. It cut down skin irritation concerns and helps prevent ‘Maskne’ (acne condition caused by extensive face mask wearing). The hydrophilic inner layer helps to absorb moisture for comfortable wearing while maintaining good breathability, especially for long hour usage.

Design and packaging

Our face masks are designed with a contoured shape for excellent fit to various face shapes. The soft elasticated earloops and flexible head ties provide the perfect fitting for every wearer. The stylish design with various colour choices makes the face masks more attractive and fashionable to wear. Safetyware face masks are packed in a bundle and seal nicely in a plastic bag for better storage against dust contamination. It provided a smart pull dispenser box to easily pull out a mask when needed.

How To Verify the Quality of the Disposable Face Mask / Particulate Respirator?

A comprehensive set of tests are being performed to validate the performance properties of the product and to classify the different mask types. From that, people can select the face mask that offers the most effective protection which matches with the international health standards.

BFE & PFE

Generally, the effectiveness of the disposable face masks can be determined by the Bacterial Filtration Efficiency (BFE) and Particle Filtration Efficiency (PFE) while the particulate respirator refer to the Most Penetrating Particle Size (MPPS) filtration efficiency.

The Bacterial Filtration Efficiency (BFE) test measures the percentage of bacteria larger than 3 microns filtered out by the mask. While the Particle Filtration Efficiency (PFE) test measures the percentage of particles larger than 1 micron filtered out by the mask. As for Most Penetrating Particle Size (MPPS), it tests the filtration of particles of 0.3-micron size.

All our face masks are of BFE & PFE > 99% while FFP2 particulate respirator have 94% effectiveness in filtering particles of 0.3micron.

Synthetic Blood Penetration Resistance

The Synthetic Blood Penetration Resistance test determines a product’s ability to act as a barrier to blood-borne pathogens. This test is required by ASTM F2100 and is tested in compliance with ASTM F1862, ASTM F2100, EN 14683, and ISO 26609. Safetyware face masks tested under these methods to ensure the product quality and masks’ safety for the wearer.

Differential Pressure

The Delta P test is performed to determine the breathability of masks by measuring the differential air pressure on either side of the test article using a manometer, at a constant flow rate. The Delta P is measured in units of mm H2O/cm2. ASTM standard requires that masks have a Delta P of less than 5.0 for good breathability.

Fluid Resistance

This test was performed to evaluate the performance of face masks to provide the protection against fluid penetration. Our face masks meet the official requirements and standards which have 80mm Hg, 120mm Hg and 160mm Hg of fluid resistance rating.

Our Products

2-Ply Medical Face Mask

- BFE≥93.6%

- Disposable,Earloop

- Hypoallergenic

- UV Sanitized & Ultrasonic Welding

- Low Breathing Resistance

- Adaptable Nose Bar

- Perfect Fitting

- Ideal For Cleanroom, Food Handling, General Industrial, Pharmaceutical & Electronics Industry

3-Ply Premium Medical Face Mask (Level II) (Earloop)

- BFE≥99%

- Disposable,Earloop

- Hypoallergenic

- UV Sanitized & Ultrasonic Welding

- Low Breathing Resistance

- Adaptable Nose Bar

- Perfect Fitting

3-Ply Premium Medical Face Mask (Level II) (Earloop)

- Made with premium quality meltblown filter which offers high Bacterial Filtration Efficiency (BFE) of ≥ 99%.

- compliance with ASTM Level 2 standard

- compliance with EN 14683-2019 Type IIR standard

- BFE & PFE > 99.9%

- UV Sanitized before packing

- Gentle on skin

- Hypoallergenic

- High Breathability

- Earloop

3-Ply Premium Medical Face Mask (Level II) (Tie-on)

- BFE≥99%

- Disposable,Tie-On

- Hypoallergenic

- UV Sanitized & Ultrasonic Welding

- Low Breathing Resistance

- Adaptable Nose Bar

- Tie-On Design Allows Adjustment of the Mask Tightness To Achieve Perfect Fitting

4-Ply Activated Carbon Face Mask (Level II) (Earloop)

- BFE≥99%

- Disposable,Earloop

- UV Sanitized & Ultrasonic Welding

- Made with Activated Carbon Layer to Filter Nuisance Odour

- Hypoallergenic & Low Breathing Resistance

- Adaptable Nose Wire For Perfect Fitting

FFP2 PARTICULATE RESPIRATOR (without / with valve / activated carbon with valve)

- Also known as N95, KN95 and P2 masks in other international standards

- Filtration efficiency of at least 94% on the most penetrating

- particle size (MPPS) - 0.3 micron

- Approved for use against oil & non-oil particulate aerosols

- Compliance to SIRIM-DOSH Approval

- Offers a more secure and closer fit to the face

- Cool latex free textile head strap for comfortable wearing

- Fold flat design offers convenient storage and portability

- Adjustable head strap buckles suitable for various facial size

- Adjustable hidden nose clip for custom & secure fit

- Continuous loop head strap design for easy hanging on mask when not in use

- Ultrasonic welded edges for better fit

- Contour design ensures the compatibility of glasses/goggles and reduced fogging

The face mask shall maintain its properties in a closed pack and stored in a cool dry condition.

Production

Frequently Asked Questions (FAQ)

1. What is the difference between a disposable face mask and a FFP2 particulate respirator?

A disposable face mask creates a physical barrier to provide the basic protection for nose and mouth from sprays, splashes, and large-particle droplets. It can help to prevent the transmission of potentially infectious respiratory secretions from the wearer to others.

The FFP2 particulate respirator is designed to achieve a very close facial fit and provides high efficiency of viruses, bacterial and airborne particles filtration. The edges of the FFP2 particulate respirator are designed to form a seal around the wearers’ nose and mouth.

2. Can the face mask / particulate respirator be washed and reused?

Both the masks are for one time use and is not recommended to wash and reuse. The filtration layer of the mask might be destroyed after washing which means the mask will no longer function as a barrier device to provide the protection against dust, pollen, virus and bacteria to the wearer.

3. Where are the face masks being made?

The face masks are made in Malaysia by Safetyware Sdn. Bhd. Our company gained the approval of the Quality Management Systems, ISO 9001:2015 certified that is internationally recognized and accepted to ensure excellent product quality control.